When you shop gas struts, you are investing in a critical component essential to various applications, including automotive hatches and office furniture. A complex and meticulous manufacturing process is the cause of the ostensibly straightforward device that promotes stability and smooth operation. Understanding the design and production processes of gas struts can offer valuable information regarding their functionality and reliability. This article focuses on the voyage of gas struts from initial design to final production, emphasising the critical stages and technological advancements involved.

- Initial Design Conceptualisation

Design and conceptualisation are the starting point for manufacturing gas struts. Engineers, designers, and architects begin by determining the exact requirements for a particular gas strut. This is based upon its intended purpose. This includes understanding the weight, the range, and any environmental conditions it must withstand.

Considerations in design include:

- The Load Capacities: This is the amount of pressure the gas strut has to exert when supporting or controlling a heavy load.

- Stroke length: The distance the strut has to travel to operate.

- Mounting points: Locations where the gas strut will be mounted and how it will interact with other components.

Advanced computer-aided software (CAD) is used to create detailed simulations and models of the gas spring. These simulations predict performance, stress, and overall functionality before proceeding to the prototyping stage.

- Material Selection

Selecting the material for the gas strut is a crucial next step. The materials selected will influence the ultimate product. Materials that are frequently encountered include:

- Aluminium: Selected for its lightweight properties and corrosion resistance.

- Lubricants: A high-quality sealant and lubricant are necessary to ensure the gas strut’s smooth operation and long life.

Materials must be able to withstand a variety of stresses and conditions, including temperature fluctuations and chemical exposure.

- Prototyping

Once the gas spring’s design is complete and the materials are chosen, a prototyping process is carried out to create a working prototype. This prototype has been rigorously tested to ensure its performance and safety.

testing includes

- Load testing: Verifies that the gas strut can handle specified load capacities.

- Durability test: Determines the performance of struts over time and repeated use.

- Testing for Environmental Conditions: This test determines whether the struts can function properly in extreme temperature and humidity conditions.

These findings are employed to optimise the design and implement the requisite modifications before mass production.

- Manufacturing and Assembly

Gas struts enter the manufacturing stage after a design has been validated. This process involves three key steps:

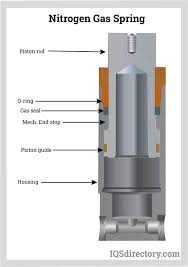

- Rods & Cylinders Fabrication: The steel or aluminium rods and cylindricals are machined according to their precise dimensions. Cutting, drilling, and assembling the components involves threading, drilling, or both.

- Filling of the Gas Chamber: Gas-chamber filling is filling the gas chamber. The gas in the chamber provides the force necessary for the gas strut to operate. The design specifications will pressurise the gas.

- Sealing: High-quality gaskets are installed to ensure smooth and leak-free operation. Proper seals are essential for maintaining the gas spring’s performance and longevity.

- Assembly: All components, such as the rods, cylinders, and gas chamber, are assembled. This step involves exact alignment and fitting to ensure that gas struts function properly.

- Qualitative Control: Each gas strut undergoes thorough quality control to ensure it meets the required standards. Visual inspections, functional tests, and pressure tests are performed.

- Packaging and Distribution

As soon as the gas struts pass the quality check, they are packaged to be distributed. The packaging protects the gas struts from damage during storage and transport. The final product’s labelling includes information about its usage and specifications to ensure correct use.

Gas struts, available in a variety of sizes and styles, can be found at retailers and suppliers. They are available to consumers for all kinds of projects, including automotive repairs and home improvements.

- Continuous Improvement

The process of manufacturing gas struts is never static. Improvements and innovations are always needed. User feedback and technological advances drive refinements to design, materials, and production techniques. Manufacturers continually review and upgrade their processes to improve performance, longevity, and efficiency.

Conclusion

The journey from design to manufacturing of a gas strut is an example of modern engineering. By understanding all the intricate steps involved—from initial design and materials selection to prototyping, assembly, and more—you gain a much deeper appreciation for technology. When you choose gas struts for your vehicle, you choose a product whose precision, durability, innovative design, and reliable performance will serve you well in many applications.